Looking Beyond the Datasheet – New Ways to Use Devices

By Isaac Sibson, Applications Engineer

Current regulators are a basic building block that can be used wherever a circuit or device needs a steady and stable source of current. They will often be used when an unstable supply can have a negative impact. For example, poor regulation could lead to a visible flicker in LED lighting. The BCR40x linear constant current LED driver from Diodes Incorporated was developed to address this and similar situations.

Almost all circuits today require some form of power regulation, and even battery-powered devices use voltage regulators. Often, the load presented by a circuit is not constant; in addition to voltage regulation, constant current drivers like the BCR40x series are used to reduce the impact of these disruptions, making sure the variable load doesn't disrupt the supply.

Another way to stabilize a power supply is to add large capacitors across the rails. These act as power reservoirs that can provide extra current for short bursts, by storing energy until needed. The nature of a capacitor means it can charge and discharge rapidly. This is a benefit when stabilizing a power supply rail, but it is a disadvantage when the capacitor becomes completely discharged. A discharged capacitor will recharge as quickly as the supply allows. If there is no series resistor in place, this could result in a large inrush current.

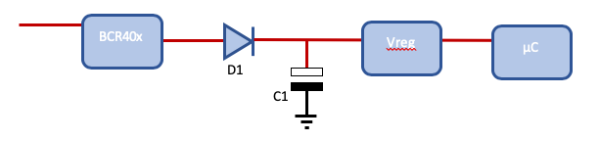

Another example of how a constant current driver can be used to good effect is below (Figure 1). The large capacitor can be viewed as just another type of variable load. By using a constant current driver to control the current available to the large capacitor, the rate of charge is set by the design engineers, and not the supply or a resistor.

Figure 1: Using a constant current regulator as a current limiter

While this isn't how a constant current driver would normally be used, it is a good example of how its basic functionality can be applied in a different way. Because the current driver is so versatile, there are many ways it can be used.

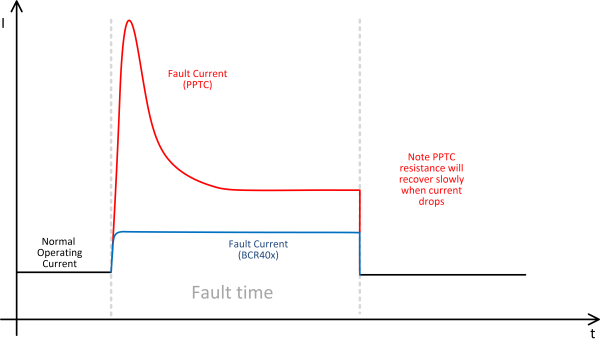

For example, in basic terms a fault condition can also be thought of as a variable load. This means it is possible to use a constant current source to protect a circuit against faults. The kind of device that might normally be used for this purpose is the resettable fuse. A resettable fuse is a device based on a material with a positive temperature coefficient, or PTC. That simply means that the resistance of the device will increase as the material gets hotter.

The resettable fuse takes advantage of this effect. Under normal circuit conditions, the PTC would be able to pass a current that doesn't cause it to self-heat. If the current increases, the residual resistance of the device will cause it to dissipate more power and, therefore, heat up. When the PTC reaches a predetermined temperature, its resistance increases significantly and rapidly. This gives the impression that a fuse has been blown, but in fact it is simple the very high resistance of the PTC that causes almost all current to stop flowing.

Unlike a conventional fuse, a resettable fuse based on a PTC material returns to its normal state once it has cooled down. After the fault condition has been removed, the device is once again able to pass the normal current without self-heating.

In the same way, a constant current source can limit the current flowing to the load, making sure it never goes above the predefined level. Because it is a regulator, the 'fault' condition would be the absolute maximum current that the driver can deliver. Under normal conditions, the current delivered would be below this absolute maximum, as shown in Figure 2.

Figure 2: Using a constant current driver as a resettable fuse

The BCR40x used here has several advantages over a conventional PTC resettable fuse. First, it will reach its 'fault' condition much faster, as it doesn't rely on a self-heating process. Second, and for the same reason, it will recover faster. In fact, because the PTC device needs to cool before resetting, it often forces the operator to power down the entire device for a period of time. The BCR40x doesn't require power cycling to 'reset', and so it is ready to operate normally as soon as the fault condition has been removed.

The BCR40x series devices cover a supply current of between 10mA and 100mA and they are available in the DFN2020 or SOT26 packages.