How Ideal Diode Controllers Ease ISO 7637-2 and ISO 16750-2 Compliance in Cars

By Jeongil Lee, Linear Power Business Unit Manager

Ideal diode controllers are widely used in automotive power system designs. They protect against reverse-polarity conditions, allowing for the control of popular 12V and 24V DC rail voltages in passenger cars and commercial vehicles, propelled via an internal combustion engine (ICE) or battery. Typical applications include engine control units (ECUs), infotainment systems, advanced driver assistance systems (ADAS), and battery management systems (BMS).

One of the challenges faced when designing these systems is to comply with the ISO 7637-2 conducted transient voltage pulses and ISO 16750-2 load dump tests. Both are important standards for automotive power systems.

ISO 7637-2

The ISO 7637-2 standard focuses on the electromagnetic compatibility (EMC) of road vehicles. It specifies test methods and procedures to ensure that electrical and electronic equipment can withstand electrical transients conducted along supply lines. These pulse transients can be caused by various events, such as switching operations or load dumps.

- Scope: Applies to 12V and 24V electrical systems in passenger cars and commercial vehicles.

- Tests: Includes bench tests for injecting and measuring transients to simulate real-world electrical disturbances.

- Importance: Ensures that automotive components can handle electrical disturbances without malfunctioning, which is crucial for vehicle safety and reliability.

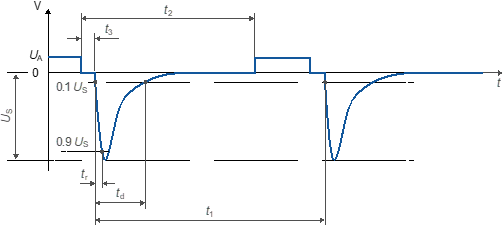

The transient immunity Test Pulse 1 is a vital test to assess the robustness of electronic devices against the voltage fluctuations that can occur when a supply is disconnected from inductive loads (see Figure 1).

Figure 1. ISO 7637-2 transient immunity Test Pulse 1 simulates transients due to supply disconnection from inductive loads

The specification parameters for ISO 7637-2 Transient Immunity Test Pulse 1 are shown in Figure 2.

|

Nominal 12V System |

Nominal 24V System |

|

|

Output Voltage (Us) |

-75V to -150V |

-300V to -600V |

|

Output Impedance (Ri) |

10ꭥ |

50ꭥ |

|

Pulse Width (td) |

2ms |

1ms |

|

Rise Time (tr) |

(1 |

(3 |

|

Pulse Repetition Period (t1a) |

>0.5s |

|

|

t2 |

200ms |

|

|

t3a |

<100µs |

|

|

a t1 shall be chosen such that it is the minimum time for the DUT to be correctly initialized before the application of the next pulse and shall be >0.5s. b t3 is the smallest possible time necessary between the disconnection of the supply source and the application of the pulse. |

||

Figure 2. ISO 7637-2 specification parameters for transient immunity Test Pulse 1 in a 12V and 24V nominal voltage system

|

|

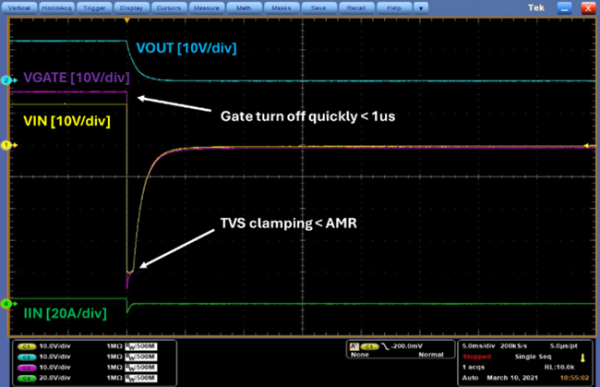

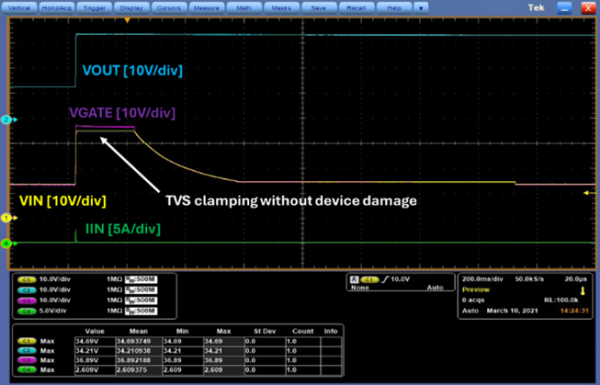

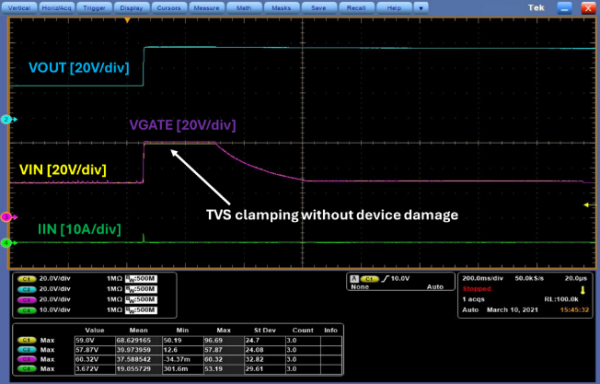

Figure 3. The AP74700Q ideal diode controller meets ISO 7637-2 pulse 1 with a 12V (left) and 24V system (right)

ISO 16750-2

The ISO 16750-2 standard addresses the environmental conditions and testing requirements for electrical and electronic equipment in road vehicles. It ensures that automotive components can withstand the various environmental stresses that they might encounter during their lifecycle.

- Scope: Covers a wide range of environmental conditions, including temperature, humidity, vibration, and electrical stress.

- Tests: Includes specific tests for load-dump protection, which simulate the sudden disconnection of a battery from the alternator.

- Importance: Ensures the durability and reliability of automotive electronics under different environmental conditions, enhancing overall vehicle safety.

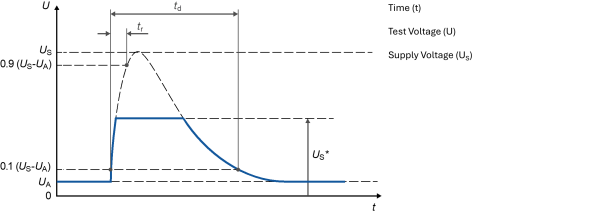

The ISO 16750-2 transient immunity Test Pulse B is one of the most destructive pulses described in the standard (see Figure 4) with centralized load dump suppression.

|

Time (t) Test Voltage (U) Supply Voltage (US) Supply Voltage of the Test Generator (UA) Duration of Pulse (td) Rising Slope (tr) |

Figure 4. ISO 16750-2 transient immunity Test Pulse B with centralized load dump suppression

The specification parameters for ISO 16750-2 transient immunity Test Pulse B are shown in Figure 5.

|

Parameters |

Type of System |

Minimum Test |

|

|

UN = 12 V |

UN = 24 V |

||

|

Usa (V) |

79 ≤ US ≤ 101 |

151 ≤ US ≤ 202 |

5 pulses at |

|

Us*(V) |

35 |

As specified by customer |

|

|

R1a (ꭥ) |

0.5 ≤ R1 ≤ 4 |

1 ≤ R1 ≤ 8 |

|

|

td (ms) |

40 ≤ td ≤ 400 |

100 ≤ td ≤ 350 |

|

|

T3 (ms) |

10 |

10 |

|

|

a If not otherwise agreed, use the upper voltage level with the upper value for internal resistance or use the lower voltage level with the lower value for internal resistance. |

|||

Figure 5. ISO 16750-2 specification parameters for transient immunity Test Pulse B in a 12V and 24V nominal voltage system

|

|

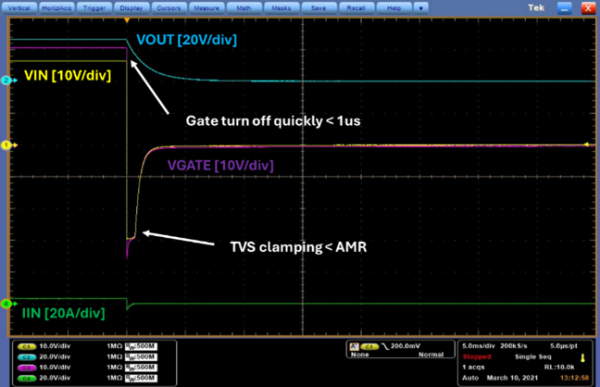

Figure 6. The AP74700Q ideal diode controller meets ISO 16750-2 Test Pulse B with centralized load dump suppression in a 12V (left) and 24V (right) system

Diodes Incorporated (Diodes) offers ideal diode controllers that meet the ISO 7637-2 transient pulses and ISO 16750-2 load dump suppression compliance standards for automotive applications (see Figure 7).

|

Component |

Input AMR Range /V |

Input Voltage Range /V |

Ext FET |

ISO 7637-2 Compliance |

ISO 16750-2 Compliance |

|

-65 to +65 |

4 to 60 |

Single |

Meets Compliance |

Meets Compliance |

|

|

-65 to +70 |

4 to 65 |

Single |

Meets Compliance |

Meets Compliance |

|

|

-34 to +65 |

4 to 60 |

Single |

Meets Compliance |

Meets Compliance |

|

|

-80 to +80 |

4 to 75 |

Dual (Back to Back) |

Meets Compliance |

Meets Compliance |

Figure 7. Ideal diode controllers from Diodes Incorporated comply with ISO 7637-2 and ISO 16750-2

Reference schematics, including proper TVS and application details, are available in the datasheets. Diodes has also released hardware boards with DC-DC and reverse voltage protection.

Automotive-compliant - AEC qualified, manufactured in sites certified to IATF 16949 and supporting PPAP documentation.

The Diodes logo is a registered trademark of Diodes Incorporated in the United States and other countries.

All trademarks are the property of their respective owners.

© 2025 Diodes Incorporated. All Rights Reserved.