Smart Appliances Need Simple and Elegant Sensors, Controllers and Timers

Everything is “smart” lately. But the brain added to your toaster needs some basic—yet elegant—peripheral controllers and sensors to be truly useful.

Look around you at all the gadgets and appliances labeled as “smart” and you’ll find impressive integrated microcontrollers, SoCs and wireless connectivity inside. In an Internet of Things (IoT) age, consumers expect their home appliances to do more—and they indeed do.

But the brains of today’s smart home appliance—MCUs and SoCs—are surrounded with basic yet hugely important peripheral devices. These peripheral sensors, timers, controllers and crystal oscillators are the sight, touch and sound “senses” that feed the home appliance’s smart brain.

Everything from toasters and window air conditioners, to coffee pots, thermostats and even smartphones rely on these elegant peripherals to help save energy, seamlessly interact with the consumer, or provide an enhanced user experience. We’ll examine three kinds of devices:

- passive IR sensors

- heating controllers

- the emerging market for Hi-Fi crystal oscillators.

See Me? Now Do Something

The Google Nest Thermostat is an example of the latest smart home appliance, not just because it has a smartphone app controlling the HVAC system, but because the device “wakes up” and activates the display when a user moves near it. Adding a passive IR (PIR) sensor and controller to an appliance can save energy by activating the device only when a human is near. PIR can also start recording, in the case of a surveillance system, only when motion and a human are detected.

Another example is the water/ice/beverage station in a refrigerator door that awakens when a user is near, not unlike motion-activated security floodlights outside one’s house (Figure 1).

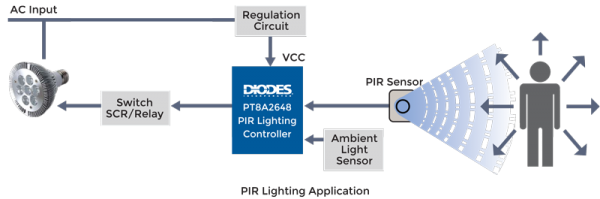

Figure 1: Passive Infrared (PIR) lighting controller diagram. (Courtesy: Diodes Incorporated.)

The PIR controller relies on a PIR sensor to detect the presence of the user’s body heat (IR) and when the ambient light sensor signals that it’s dark enough to turn on the lights. The signal processor (controller) activates the SCR or relay, and the lights illuminate. The system seems simple enough, but Figure 2 reveals there’s more to it. Sensor inputs feed the controller, and mixed signal analog and digital logic control different loads: which can be lights as shown, HVAC duct dampers, moving cameras, and so on.

Digging deeper, the diagram shows two-stage amplifiers with adjustable gain (sensor sensitivity) set through an external resistor value. An integrated low-dropout (linear) regulator or LDO removes noise from the external power supply, which enhances reliability. Built-in output delay oscillators give the user the flexibility to adjust output duration. Finally, there’s a CDS (for a CdS or equivalent photoresistor) function to automatically detect ambient light.

Figure 2: Functional block diagram of the PIR controller shown in Figure 1. (Courtesy: Diodes Incorporated.)

An example of the controller in Figure 2 is Diodes Incorporated PT8A2648 PIR Sensor – Relay Driver. The CMOS device is ideal for lamp control and includes a 2-wire op amp for use with TRIACs or a 3-wire op amp to control a relay for higher current loads. What’s interesting about this particular device is the on-chip integration and programmability. Besides the aforementioned op amps, there’s also onboard system and output timing oscillators that save external components; a timer to set ON/OFF delay; and a CDS function to detect ambient light that uses an additional sensor to only activate the load when needed regardless of the IR motion/heat.

According to a Diodes Incorporated spokesperson, the critical parameters for a PIR controller are noise rejection, sensitivity and reliability. Collectively, these features assure no false alarms (turning on the load when no human is present), as well as “playing nice” with all kinds of sensors via adjustable sensitivity. Sensitivity adjustment allows a programmable detection range—useful if you’re a thermostat or a flood lamp. The device is also tiny, available in a 16-pin DIP or SOIC package.

Touch: The Heat is On

From toasters to kettles and coffee, and curling irons to clothes irons, resistive heat appliances warm, boil, kink and flatten consumer goods. And since their invention in the 1900s, they’re finally getting “smart” as safety, connectivity, user interface (UI) and energy conservation take center stage. My own toaster has a “bread brain” that does an incredible job of evenly and consistently making toast. Although not controlled via a home network as are some of the latest coffee pots, my toaster has sensors and a heating controller inside.

The array of considerations in heat-based appliances is shown in Figure 3. Op amps, PWM, zener diode (ZC in Figure), TRIAC and SCR blocks refer to the method of controlling the heat loads, while timers, ADC, comparator and LCD connect to sensors and the UI. You wouldn’t expect it from a simple electric teapot, but there’s a lot of functionality going on.

The battery discharger controller, for example, makes possible such safety features as over- temperature protection and short circuit protection by removing the residual capacitance from the load to prevent shock at the cord’s prongs.

Figure 3: Requirements for heat controllers. (Courtesy: Diodes Incorporated.)

Resistive heat appliances consume up to 1500 W doing their job; that’s a lot of amperage and heat (about 5,118 BTU/hr or 1.5K J/s). Switching on over 10A (at 120VAC) can cause serious EMI due to voltage spikes unless the load is energized as the AC sine wave amplitude reduces to zero before switching polarity. Controllers that detect this “zero cross” point remove spark potential, reduce EMI, and extend relay lifetime.

Of course, the load that creates the heat is at the core of the appliance regardless of its function; designers expect accurate temperature control to differentiate their product’s features and keep consumers safe.

Safety is paramount during operation and after. Controllers need to meet the expected use case (activating the load(s) and turning off), while also assuring no overload, thermal runaway, or inadvertent unintended operation. A device shouldn’t spontaneously turn itself on. And even when it is off, the appliance shouldn’t draw much energy while in standby. In fact, since January 2013, European Directive 2005/32/EC LOT6 has mandated that an appliance shall not exceed 0.5W in standby.

While some devices like a toaster or iron should turn off after a while for safety, some need to “keep warm” while driving a display or indicator to inform the user. A smart kettle is such an example, as is a curling iron that awakens when the user picks it up when it’s not in standby.

As if these use cases weren’t enough, resistive appliances create heat through several different means. Heating elements change resistance with heat and thermistor-based positive temperature coefficient (PTC) elements allow rapid temperature rise. Negative temperature coefficient elements (NTC) allow more gradual heating that slows as temperature rises. Both types of elements need to be controlled. And elements can be heating wire, mica (PTC), or metal ceramic (MCH). Add in the functions and flavors shown in Figure 3, and you have a non-trivial block diagram like that found in Figure 4.

Figure 4: Block diagram for a typical resistive heat appliance. (Courtesy: Diodes Incorporated.)

Diodes Incorporated covers this market with a range of heat controllers specifically targeting toasters, kettles, coffee makers and curlers. Diodes Incorporated heat controller builds in all the discrete components needed for heat devices and adds algorithm-based control plus a variety of output load options. The company’s PT8A3362 for “e-curler” applications, for example, supports dual AC power levels, eleven temperature settings with auto off feature, along with multiple buttons and LCD display.

Sounds Even Better

The last home appliance that deserves mention is the venerable smartphone, but not for the reason one might expect. While my iPhone 6 sounds much better than my first iPhone 3G, audiophiles demand even more. Some smartphone manufacturers looking for ways to differentiate their products are turning to high-quality audio to reel-in audiophile customers. The appeal of deep bass and crystal treble is compelling, especially when a user compares typical smartphone audio with “Hi-Fi” audio.

To add more dimension to the sound field (e.g., more bits per sample) with lower total harmonic distortion (THD), and wider dynamic range (DNR), expensive audio-quality DACs such as ESS Technology’s Sabre family are used externally to the smartphone’s SoC baseband or application processor (Figure 5). Audio DACs also from Wolfson, Cirrus Logic and others do the trick, but each demands clock sources that are as “clean” as possible.

Figure 5: Audiophile-quality smartphone sound requires high-end components. (Courtesy: Diodes Incorporated.)

ESS’s ES9018 DAC shown in Figure 5 is a 32-bit device that spans 129 dB DNR (stereo) and beyond 135 dB with a mono source. THD is an astounding -120dB and the device can sample at over 1.5MHz and even output to 8 channels (for surround sound, not a smartphone). The secret to the device’s popularity is programmability of the interface and the onboard algorithms that process the audio prior to the analog output stage. ESS included a “jitter reduction” block immediately preceding the DAC to smooth the sample curves and reduce time wandering (Figure 6).

Figure 6: A super high-quality audio DAC like this from ESS pays special attention to jitter and requires an XO time source that is equal in DNR, while minimizing jitter and phase noise. (Courtesy: ESS Technology.)

Any time domain jitter present in the clock source crystal oscillator (XO) to a high-quality DAC like the ES9018 will translate into phase noise in the frequency domain during signal processing. In short, a high-quality audio DAC needs a high-quality XO; commodity XO devices won’t allow the DAC to produce acceptable audio.

The audio’s quality is especially noticeable at low frequencies where jitter (time domain) and phase noise (frequency domain) are audible. HiFi XO’s like Diodes Incorporated PT7C5127K/P series, sampling in 2016 Q2, boast very low phase noise, with an “outstanding close-in phase noise performance” in the 1Hx to 1KHz offset range. Moreover, the device is available in a wide temperature range that matches the typical smartphone use case. (https://www.diodes.com/products/connectivity-and-timing/crystal-and-crystal-oscillator/)